Longking fluid simulation center was established in 2005, which is specialized in the research of CFD simulation technology in ESP, desulfurization and DeNOx. We've been cooperated with many universities both from home and abroad, such as Tsinghua University, Zhejiang University, University of new south wales from Australia, Monash University, Granular Technology Pty Ltd, Southeast University, North China Electric Power, Wuhan University of Science and Technology, Shanghai Jiaotong University, etc. At present, longking fluid simulation center has been equipped with mature and perfect CFD simulation technology in the design of electric (bag) dust removal, denitrification, desulfurization, and flue gas treatment island, etc. It has undertaken more than 500 CFD simulation projects of dust removal, desulfurization and denitrification projects at home and abroad, and has rich engineering practice experience.

Test Instrument: KANOMA interlligent environment tester, YC521N-k thermometer

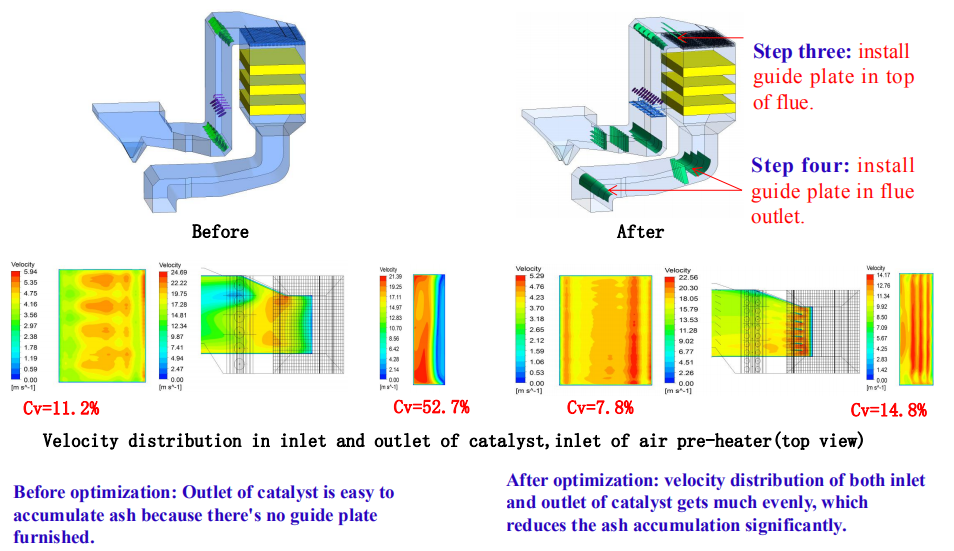

Flow field is the key factor that affects the NOx removal effiency, ammonia slip rate and catalyst life.

Problems exist in SCR DeNOx system:

Low DeNOx effiency, high ammonia slip rate, catalyst erosion and plugging, high pressure drop, heavy dust in stack, plugging in air preheater.

Contact:

Phone: 0086-13179322202

Tel: 0086-515-88515388

Email: info@longkingcotech.com

Add: 201106, 3F, Bldg 10, NO.55 Nanhua Str. Shanghai, China