Main Process and Characteristics of LongkingCotech's Catalyst Regeneration

LongkingCotech introduced catalyst regeneration technology from US, and can provide catalyst regeneration service for honeycomb catalyst, plate catalyst, corrugated catalyst etc. The regenerated catalyst can achieve the same high performance as fresh catalyst.

Main regeneration process:

Make regeneration process plan.

After carefully testing and analysis by the laboratory, and compared with the existing powerful database, customize the best solution for regeneration plan;

Pretreatment

Remove the fly ash and other particles on the surface and ash in pores of the deactivated catalyst.

Physical chemical cleaning.

Remove all surface sediments,open all pores and micropores, make the specific surface area get restored. At the same time,the chemical poisoning substances attached to the active sites are also will be cleaned,so that the activity can be restored.

Intermediate heat treatment.

Drying the cleaned catalyst to remove the moisture from the pores of catalyst, in order to implant the active components of the catalyst.

Activity implants.

Uniformly loading the active component into the micropores of the catalyst,fully recovery the activity of the catalyst.

Final heat treatment.

Recalcination, a heated drying process that re-establishes mechanical strength and fixation of the active metal oxides.

Inspection and Testing

In the regeneration process, withdraw sample elements for testing to ensure the performance to meet the requirement.

Packaging and shipping.

Replace the defective catalyst units, harden the windward side; reinforce the packaging and prepare for shipping.

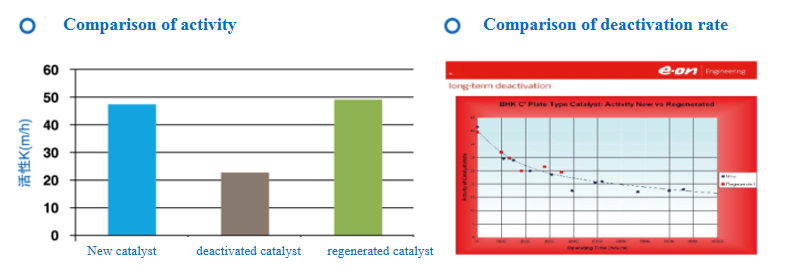

Performance comparison before and after regeneration :

Contact:

Phone: 0086-13179322202

Tel: 0086-515-88515388

Email: info@longkingcotech.com

Add: 201106, 3F, Bldg 10, NO.55 Nanhua Str. Shanghai, China